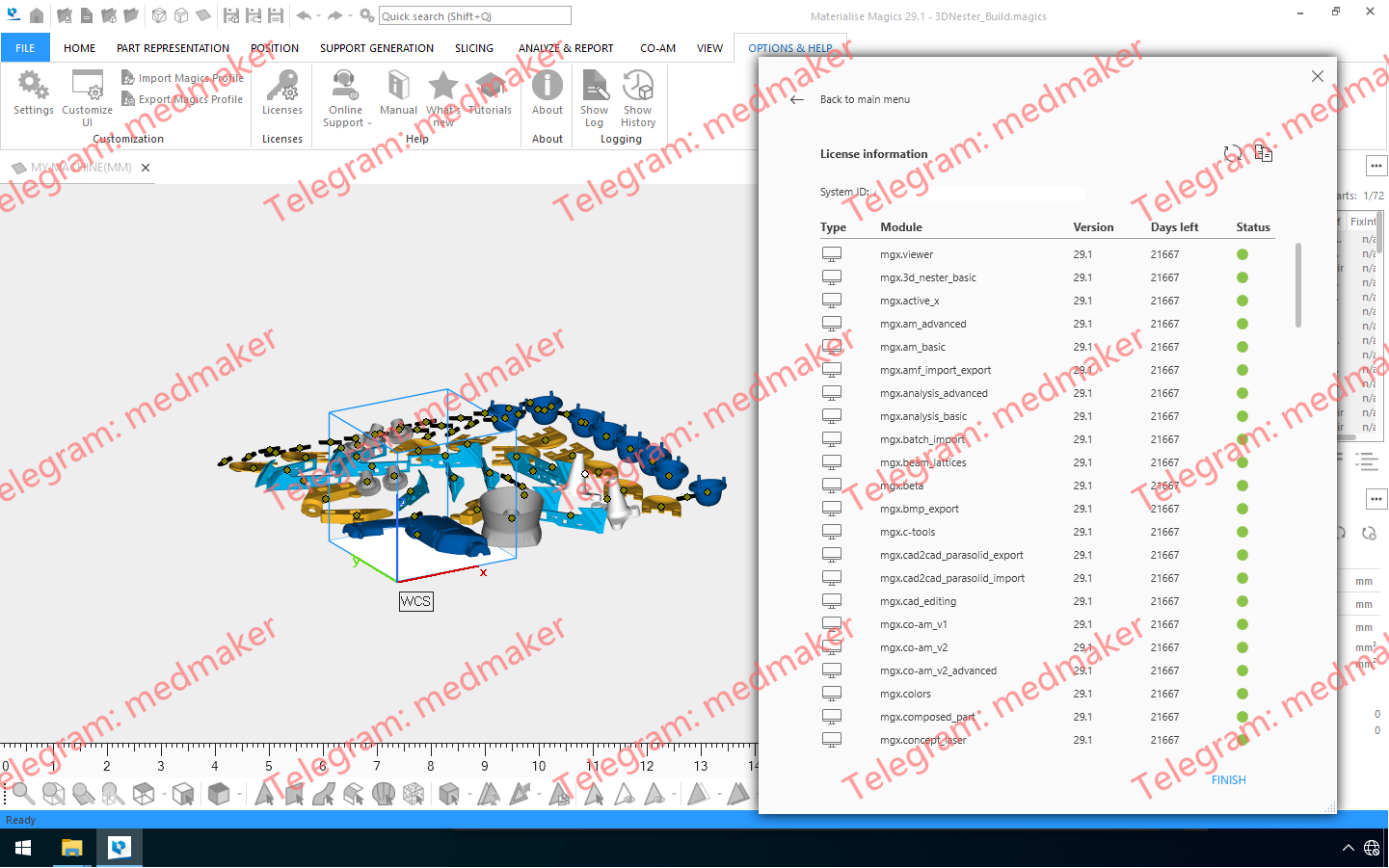

Materialise Magics 29.1.1

Materialise Magics 29.1 simplify and optimize data and build preparation with Magics — our comprehensive, industry-leadi...

Materialise Magics 29.1 simplify and optimize data and build preparation with Magics — our comprehensive, industry-leadi...

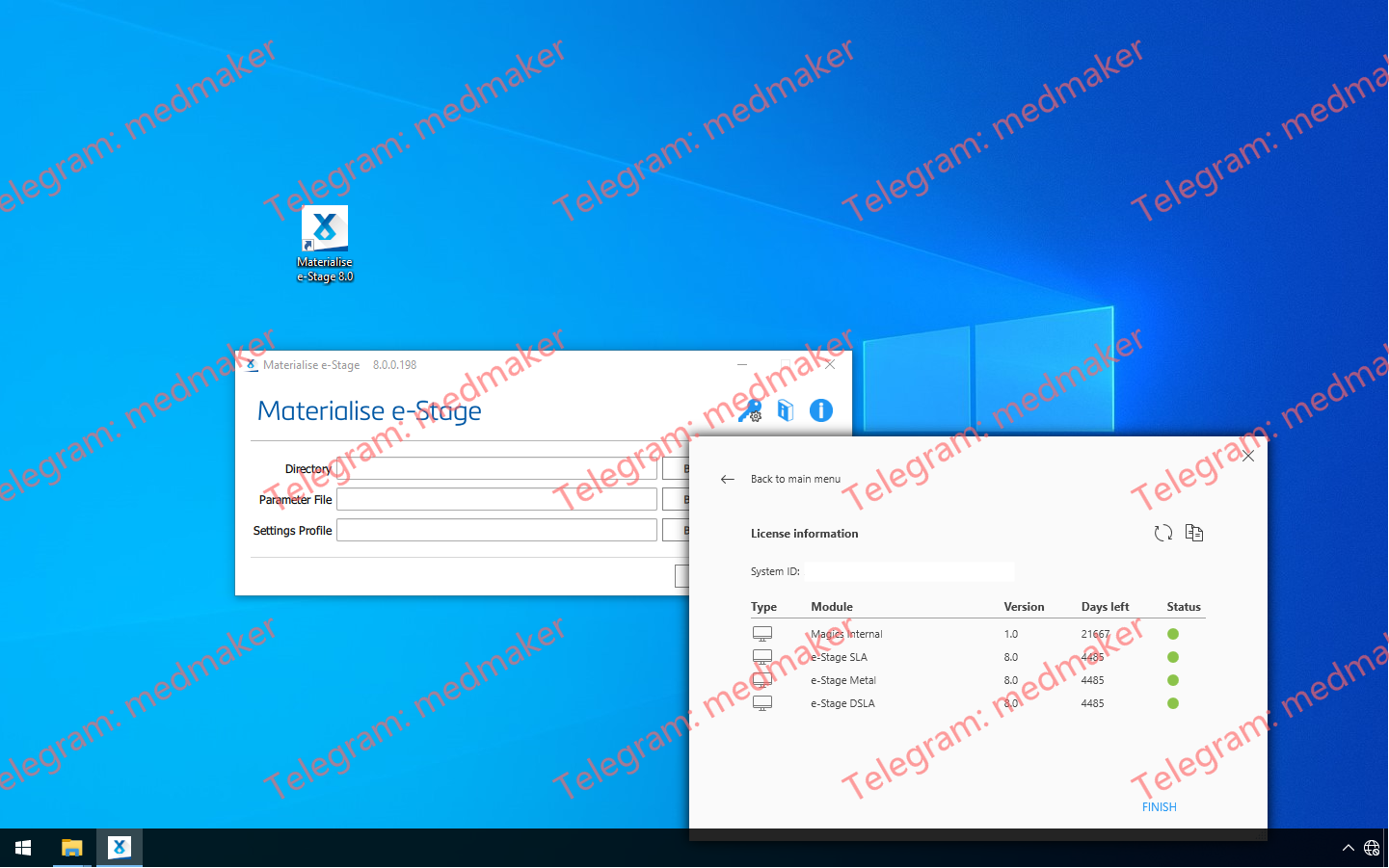

With e-Stage you can fully automate support generation to achieve these goals during every stage — from data preparation...

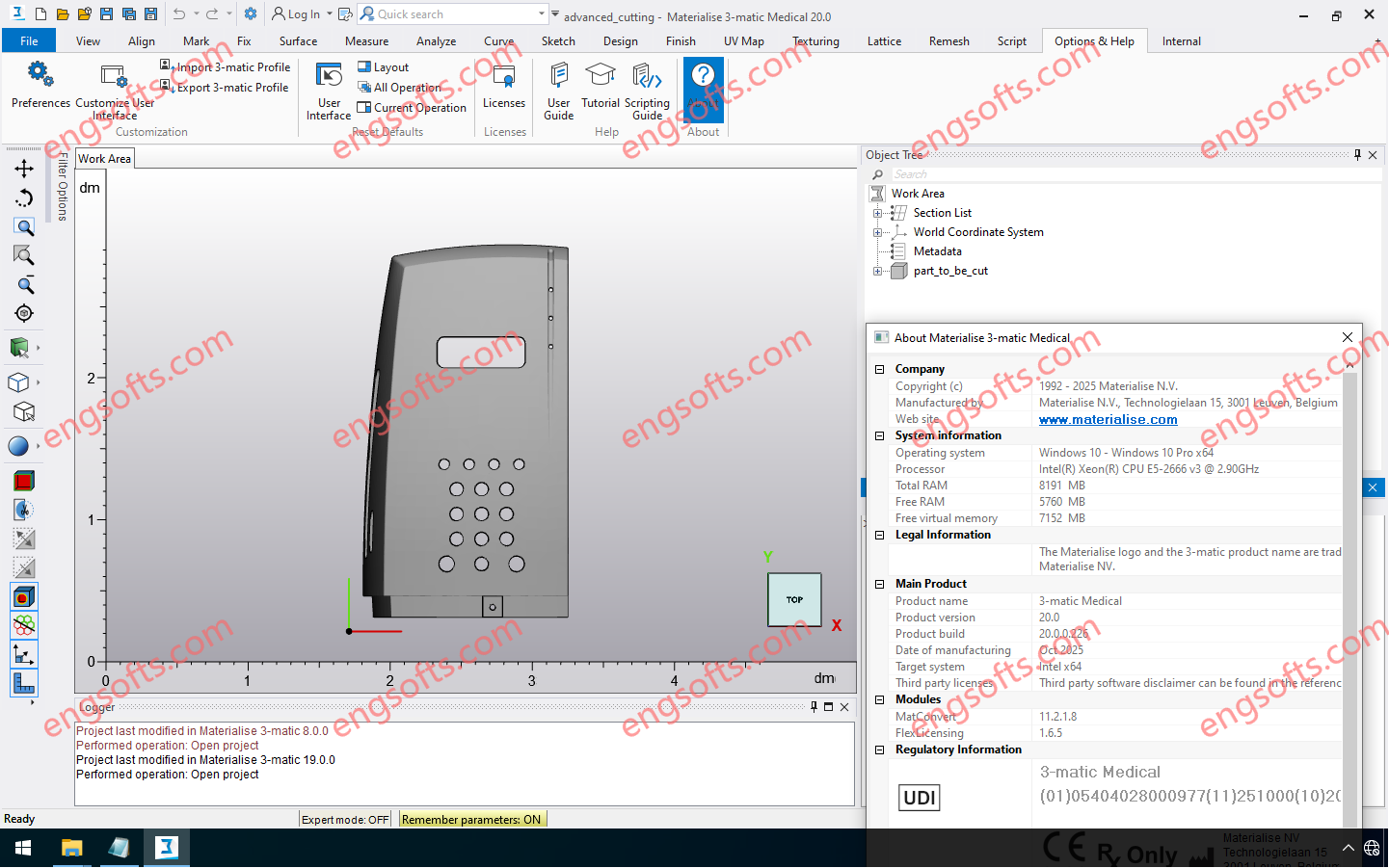

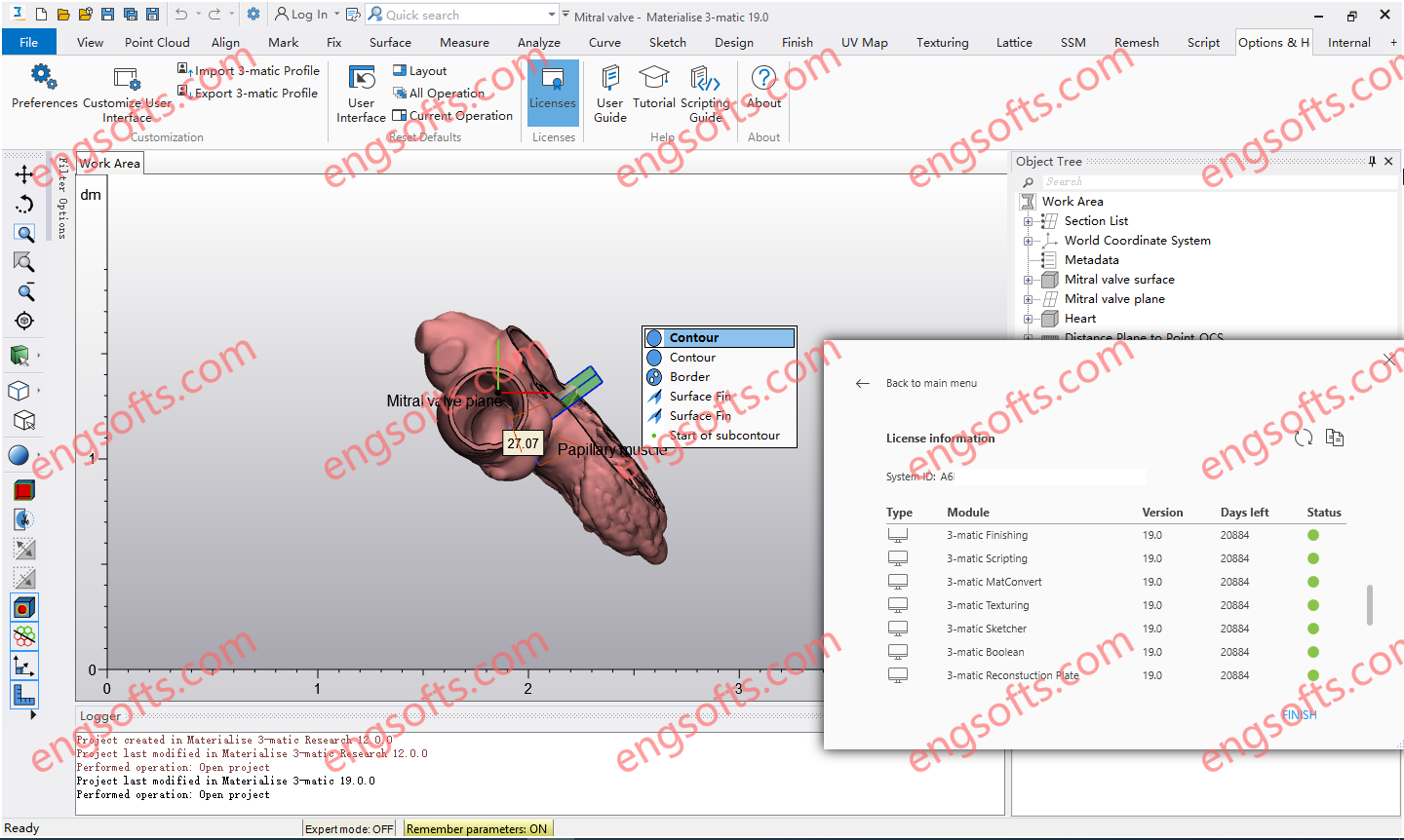

Materialise 3-matic Medical design personalized guides and implants, print anatomical 3D models, and develop representat...

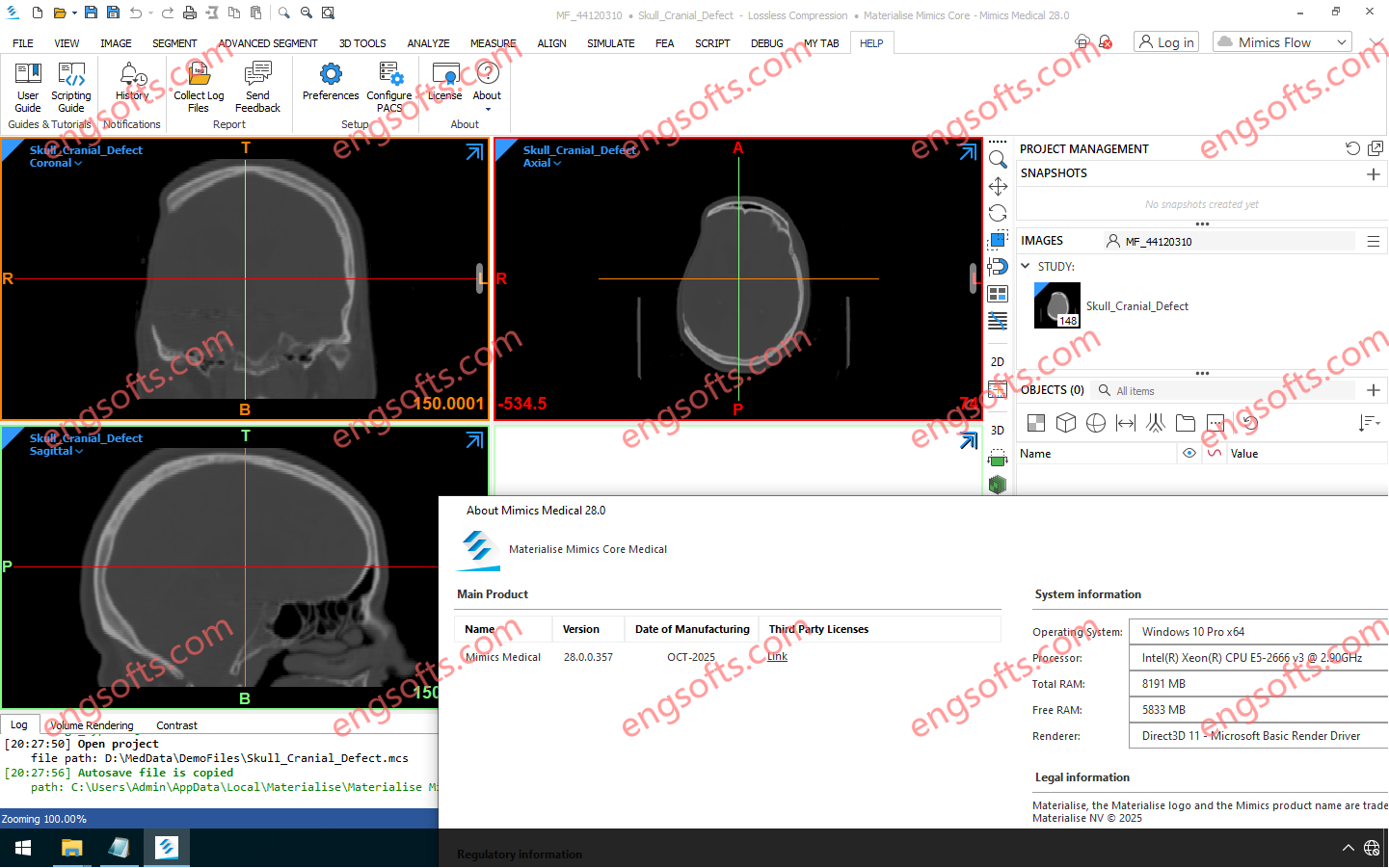

Materialise Mimics Core with 3-matics move from 3D medical image data to 3D modeling efficiently and accurately. Mimics ...

Materialise Mimics Core is a 3D medical image segmentation software,Move from 3D medical image data to 3D modeling effic...

3-matic enables you to clean up rough data from a CAD design, topology-optimized model, simulation, or scanned data by m...

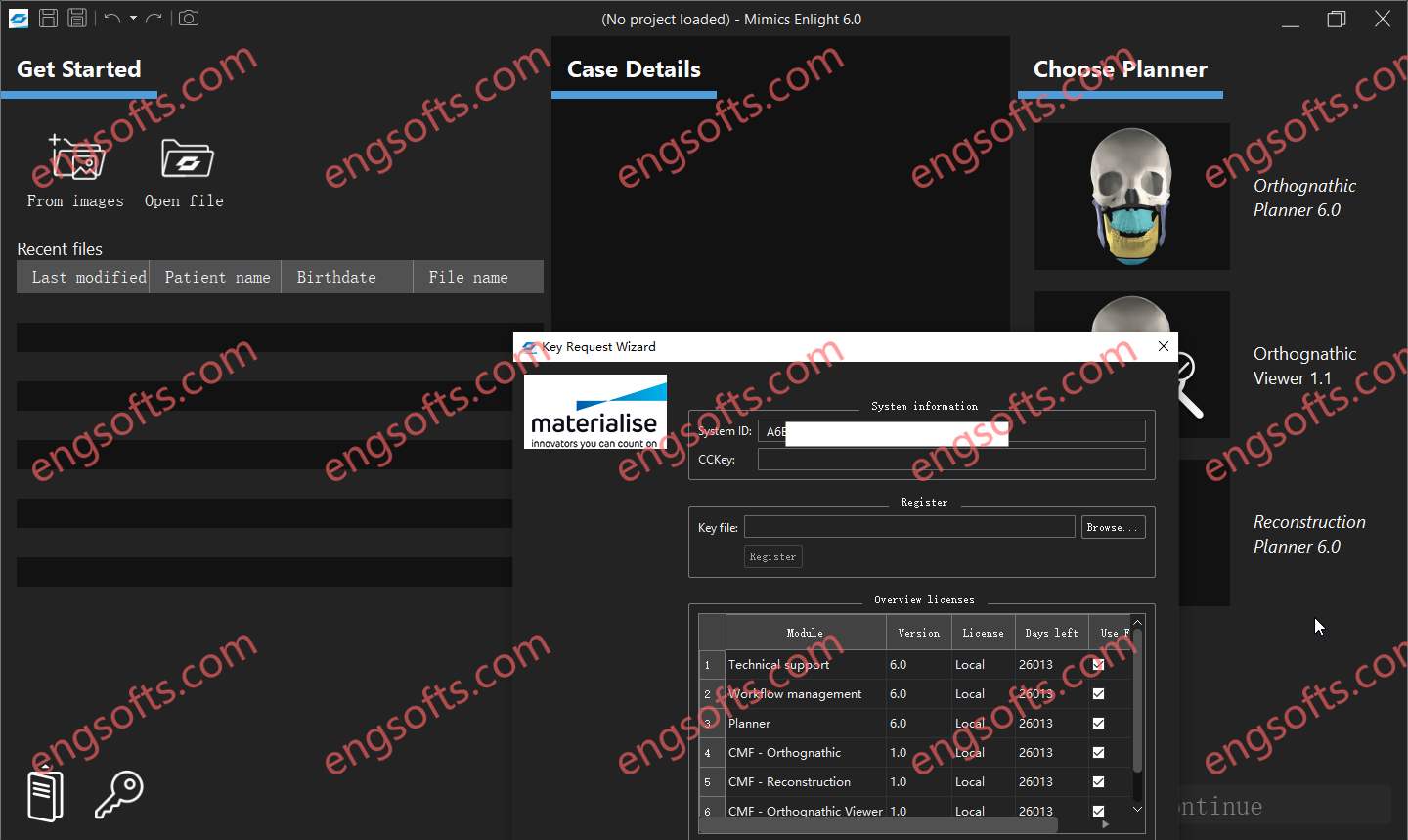

Mimics Enlight CMF is intended for use as a software interface and imaging segmentation system for the transfer of medic...