SFTC provides up-to-date release notes for the DEFORM system v14.0.1. This article contains information about recent important change, bug fixes, and updates to existing features.

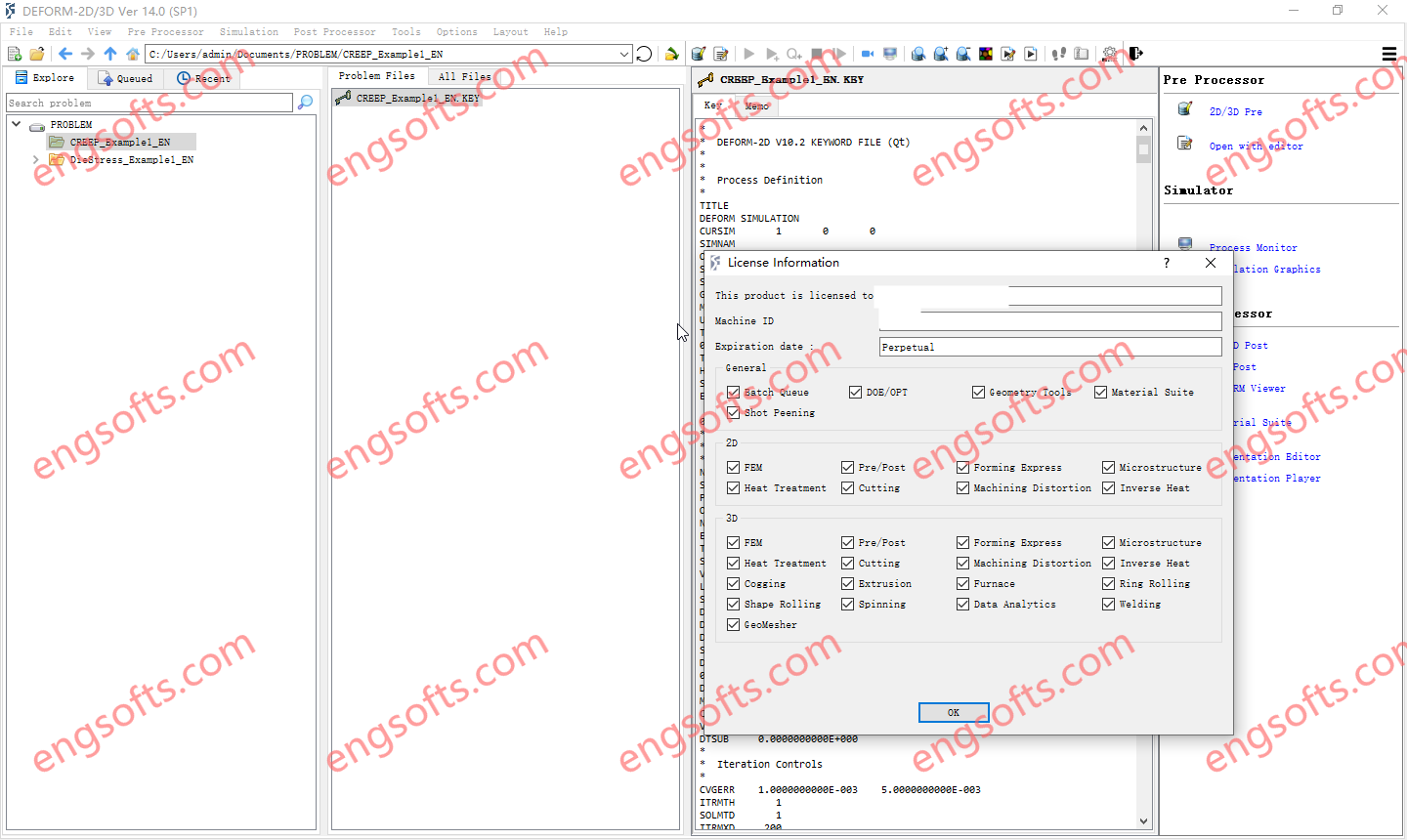

SFTC DEFORM 14.0.1 Tested Picture

DEFORM v14.0.1 is supported for the Windows operating system. Linux support will be addressed in an upcoming release (v14.0.2).

- DEFORM v14.0.1 (Service Pack 1) includes important bug fixes related to the graphical user interface (GUI) applications and minor system updates, based on feedback from DEFORM customers and distributors using the v14.0 system.

- There are no changes to the FEM engines, AMG (meshing) modules, License Manager, or DEFORM Service Control programs in this update.

- As a result, the DEFORM v14.0.1 package contains the same License Manager (LM) and DEFORM Service Control (SC) programs as v14.0, with their version numbers remaining unchanged from v14.0.

Highlights of New and Enhanced Features

Majority of the highlights of v14.0.1 DEFORM system were presented in the Spring 2024 DEFORM User Group meeting and the Fall 2023 DEFORM User Group meetings.

- Partial domain solver which was introduced in the Spring 2023 DEFORM Users Group meeting has been tested/validated and now officially available in v14.0/v14.0.1. It will help to reduce a computational cost in incremental/rotary forming process simulations like spinning, flow forming, and orbital forming.

- CFD solver is available with GUI implementation for gas quenching simulation in v14.0/v14.0.1. CFD flow simulation can generate the heat transfer coefficient (HTC) profile and then quenching/distortion simulation can be conducted using the calculated HTC. 3D Lab document for gas quenching is available in v14.0 official release.

- Induction heating model now can model B-H curve and hysteresis loss. New state variables (magnetic field intensity H, magnetic flux density, B) have been added to better present induction heating simulation results.

- New constitutive models of Elasto-plastic porous model, General Neo-Hookean model (Hyperelastic) have been added.

- New yield criteria of Barlat Anisotropy 1991 has been introduced.

- New hardening model of Yoshida Uemori has been introduced.

- Hydraulic press movement enhancement. Multiple ram press movement model has been newly developed and introduced.

- 3rd rotation movement option is add in 3D.

- Ring rolling model enhancement. It now can support user-selected ring diameter location for stopping and movement control usage. Advanced movement control option like a PID control has been added.

- Shape rolling model enhancement. It now can support Tet mesh (with Boolean and Force remesh options). Various user-enhancement requests were implemented for easier setup of multi-pass shape rolling process.

- 2D adaptive contact bcc has been developed in 2D FEM. It can be helpful in forging simulation with multiple deforming dies.

- Mechanism-based dynamic recrystallization of Aluminum alloys has been developed.

- Precipitation hardening model (based on classical nucleation and growth theories) has been developed.

- Crystal plasticity for texture model has been developed.

- For easier handling of many inter-object relations, Examine tool for inter-object relations and Explode view have been developed.

- Thermal (Proximity) contact has been introduced for accurate temperature prediction in sheet forming applications with thermal calculation.

- Many new user-friendly enhancements have been made in Process Monitor, DEFORM Setup, License Monitoring tool.

Must log in before commenting!

Sign Up