Digimat is the state-of-the-art multiscale material modelling platform focusing on the micromechanical modelling of complex multiphase materials such as plastics, composites, metals, and elastomers, revealing how they perform at part and system levels. Digimat bridges the gap between materials, manufacturing processes, and structural part performance to design innovative high-performance products while minimising weight, cost and time-to-market.

Available versions: 2024.x , 2023.x , …

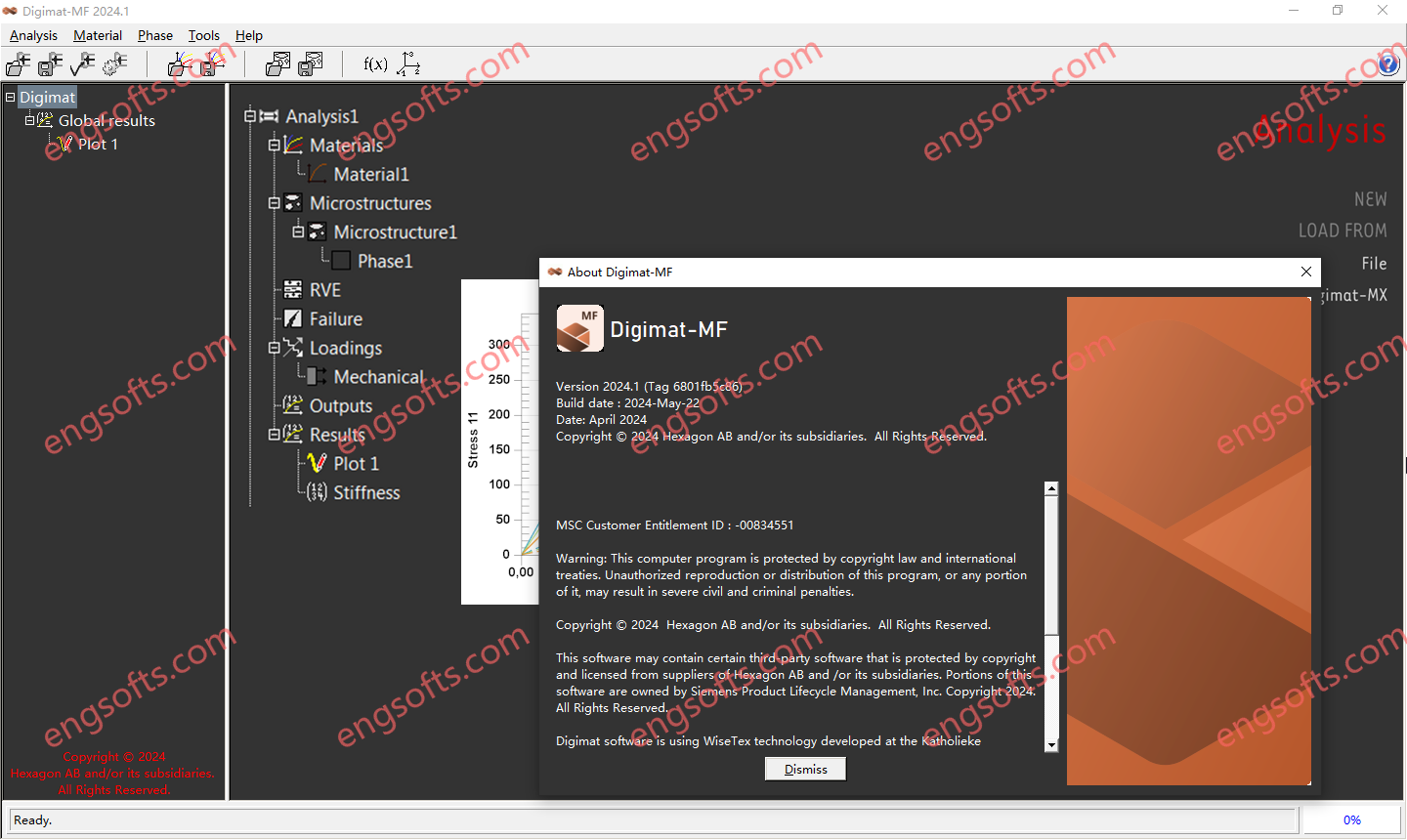

MSC Digimat 2024.1 Tested Picture

MSC Digimat 2024.2 Release Highlights

- Electrochemical modelling of batteries: Digimat-FE introduces the electrochemical simulation of Li-ion and Na-based batteries, offering predefined analysis setups with easy access to a comprehensive material database. Users can import battery cell microstructures from CT-scan images or generate them synthetically. Charging profiles are customisable with various electrical loading steps. This new capability provides detailed insights into battery cell performance, through macroscopic response, key performance indicators and in-depth field results.

- Material variability and design of experiments: Digimat-MS allows users to account for material variability, including stiffness, strain at break, and stress at break, using design of experiments (DoE). Multiple simulations can be run locally or remotely to assess the impact of material variability on the structural performance of the short fibre reinforced plastic components. Component failure can be analysed through interactive visualisations such as scatter plot matrices, parallel coordinates plots, and correlation heatmaps.

- Material data exchange with Nexus Materials: With Digimat 2024.2, users can seamlessly exchange material data between Digimat-MX and Nexus Materials Connect. The effortless operation allows users to quickly generate additional material data under different conditions, such as temperatures or fibre content, with just a few clicks in Nexus Materials Enrich.

- Fastener pull-through tests: The tests database of Digimat-VA has been expanded to include fastener pull-through tests according to the ASTM D7332 standard, enabling engineers to evaluate the out-of-plane behaviour.

- Strain rate elastoplastic calibration from creep data: Users can enjoy a new workflow in Digimat-MX for efficiently calibrating strain rate elastoplastic (SREP) material cards using both tensile and creep experimental data. This enhanced workflow also supports FEA validation for both data types, ensuring reliable results. Additionally, the strain rate dependent calibration method is also integrated into the reverse engineering of a strain rate dependent failure indicator.