EDGECAM 2025.1 release encapsulates amplified productivity with enhanced Turning, Milling, and WireEDM operations. It brings pioneering cycles for improved CNC programming, facilitating high-level machine utilization. For 5-axis machine users, automation upgrades promise production scaling. Our consistent enhancements are aimed at advanced control, smarter toolpath separation, and intelligent function integration, driving optimal cycle time and minimized manual interference.

Available versions: 2025.x ,2024.x ,2023.x ,…

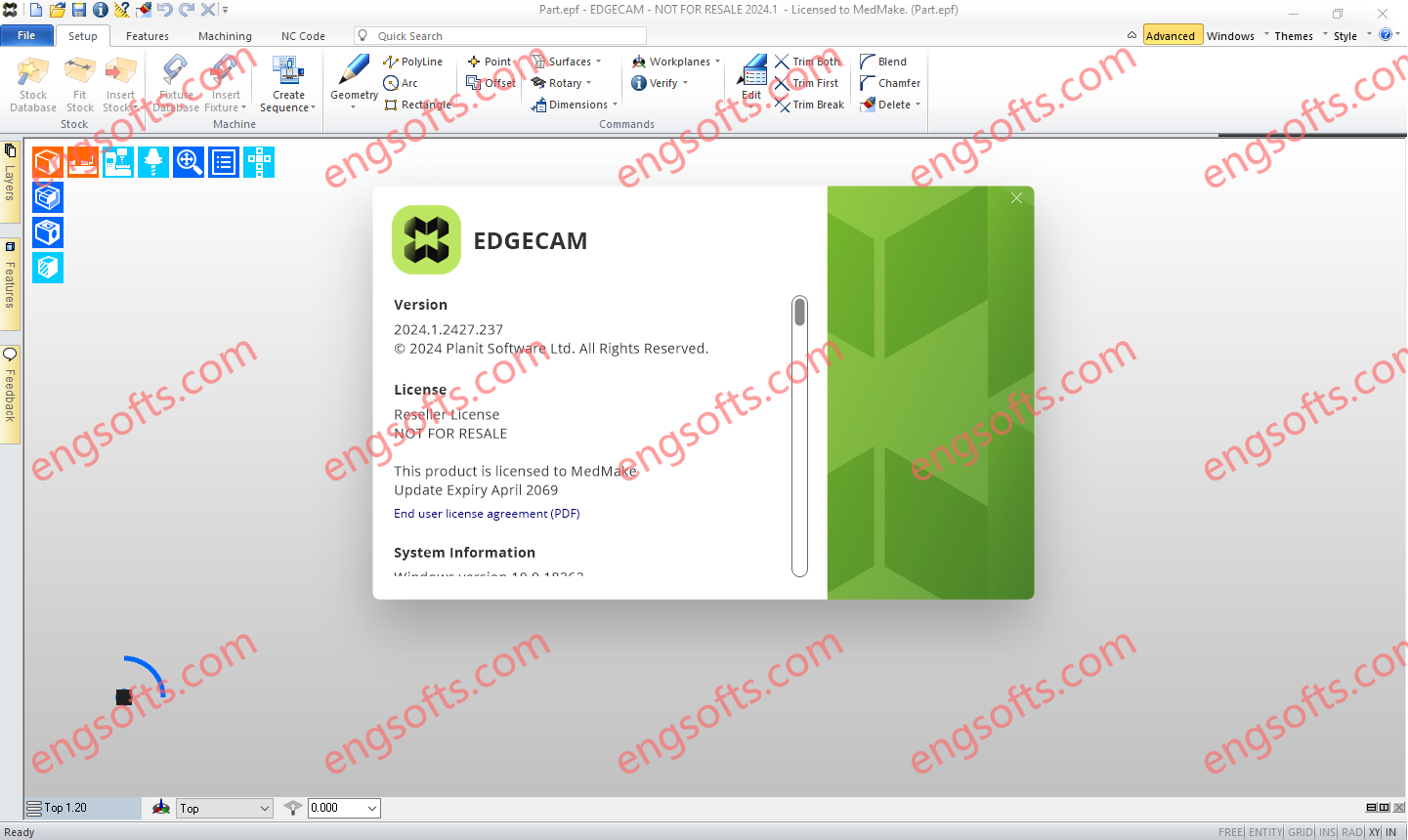

Hexagon Edgecam 2024.1 2435 Tested Picture

EDGECAM version 2025.1 Release Highlight

Built to Get CNC Programming Done Faster

Released with a powerful set of enhancements designed to accelerate productivity, optimize machining processes, and deliver an even more intuitive programming experience. From Wire EDM to 2-axis turning, 3-axis milling, and all the way to 6-axis machining, EDGECAM 2025.1 delivers enhancements across the board to speed up your workflow and boost shop-floor efficiency.

Top Highlights – EDGECAM 2025.1

- Smarter Automation: upgraded Technology Assistant and PCI-driven Five-Axis strategies boost repeatability and speed.

- Enhanced Simulation: Advanced, mesh-based comparison delivers more visual and precise verification of toolpaths.

- Race Line Finishing Cycle: A new intelligent milling cycle that automatically finds the fastest path across complex profiles to reduce cycle time.

- Stronger Security: Your database runs on Microsoft SQL Server 2022 with TLS 1.3 support for faster, more secure operations.

- Cloud Connectivity: NEXUS 3D Whiteboard for real-time sharing of parts, tooling, and setups.

Enhanced Automation

Users will have greater control when automatically determining cutting data thanks to EDGCAM 2025.1 enhancing not only its ‘Technology Types’ but also adding turning data to its ‘Depth of Cut’ algorithm. The overall effect will be greater control when using the Technology Assistant.

EDGECAM 2025. 1 delivers a better user experience for customers working with multiple components by enhancing Fixture and Stock identification. Extended names are now easily identified through various display windows and the data is accessible to the code generator and macro scripts.

Cloud Connectivity

Nexus Apps: EDGECAM is now cloud-connected, allowing users to share projects and collaborate using the NEXUS platform. The 3D whiteboard feature enables users to share complete machine setups and collaborate on design reviews, either on the actual part or on the fixture on the tooling design.

Turning Enhancements

- B-Axis Contour Cycle Support: Mill-Turn users with 5-axis head-table rotary machines can now program and simulate B-axis turning toolpaths, unlocking more flexibility and efficiency.

- Advanced Turning Enhancements: Turning automation is boosted by smarter Depth of Cut logic, enhancing precision and control in complex parts.

Milling Enhancements

- Race Line Finishing Cycle: A new high-speed toolpath designed for machining complex profiles such as gearbox sealing faces and precision castings. Includes automatic fixture detection and stock sensitivity.

- Parallel Lace Cycle: New “Point Distribution” control allows for finer toolpath resolution, improving surface finish and NC code quality.

- Rough Milling – Prioritise Additional Cuts: Ensures gouge-free toolpaths for complex multi-region components by optimizing cutting order dynamically.

- Profiling Enhancements: Extended helical support improves surface finish and reduces cycle time on undercut components.

Guides, Toolstore & Simulation

- Improved Fixture and Stock Recognition: Better naming conventions and display help streamline multi-component setups and make data more accessible to post-processors and macros.

- ToolStore Security Upgrade: Upgraded to SQL Server 2022 with support for TLS 1.3, ideal for projects requiring high data protection.

- Simulation Enhancements: The new mesh-based comparison in the simulator allows interactive analysis for a more visual and dynamic validation process.

Five Axis Perfection

- Automatic Lead Type: Removes guesswork when defining entry and exit strategies, making 5-axis programming more efficient.

- Flowline Strategy: Adds greater control and smoother finishes on individual component faces.

- Multiaxis Enhancements:

- Avoid Small Profile Ramp: Better ramp diameter control.

- Trim Line Ramps: Dynamic toolpath adjustment based on stock.

- Fade Lead In/Out: New option for smoother transitions.

- Floor Parallel Pattern: Improved surface quality for wall finishing.

评论前必须登录!

注册