MSC Easy5 2025.1

Easy5 simplifies the construction and analysis of such systems with a graphical, schematic-based application. A comprehe...

Easy5 simplifies the construction and analysis of such systems with a graphical, schematic-based application. A comprehe...

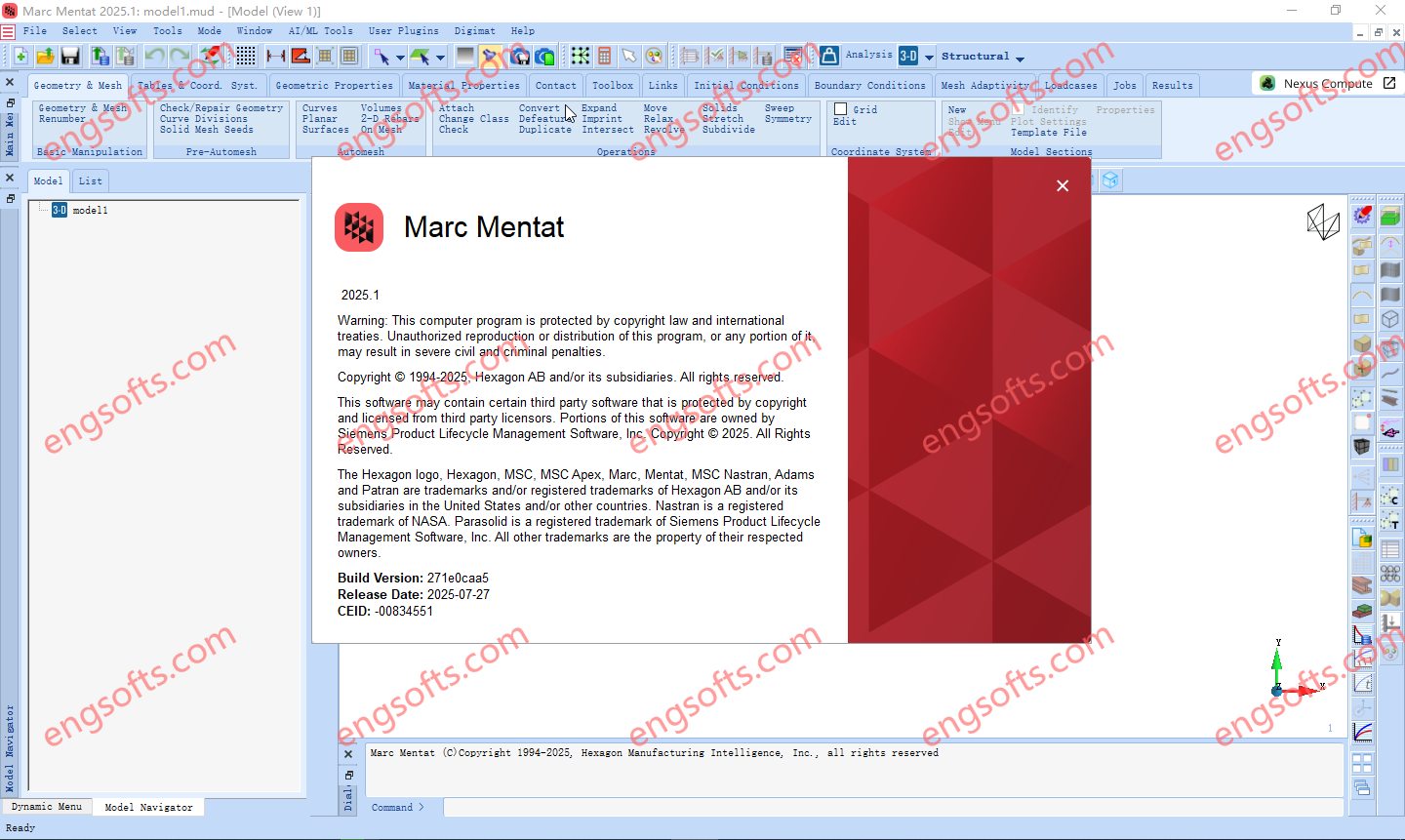

Marc 2025.1 includes full support for units during pre-processing, new temperature-dependent superelements, a new non-li...

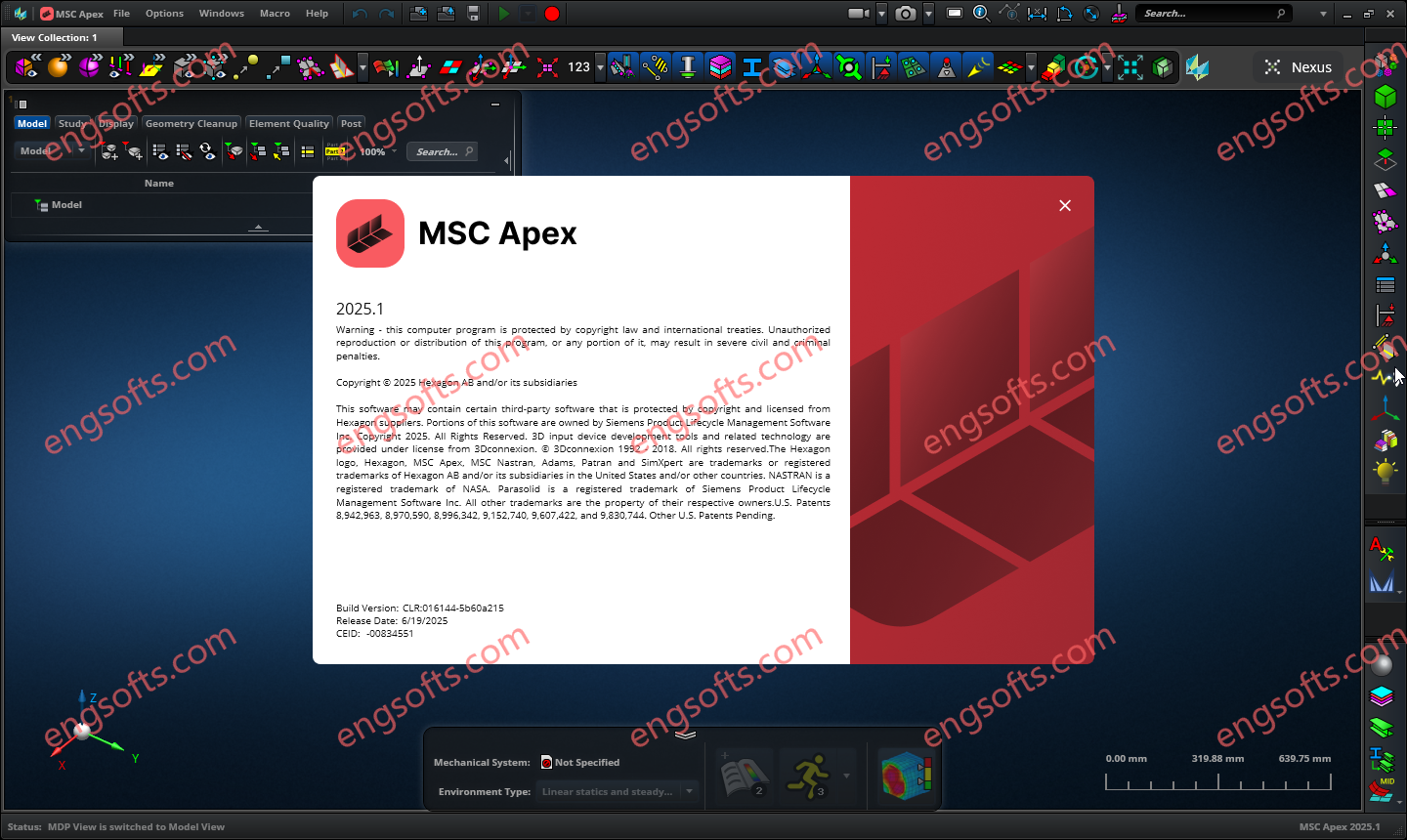

MSC Apex 2025.1 introduces a significant stride in developing comprehensive beam functionality, while also delivering su...

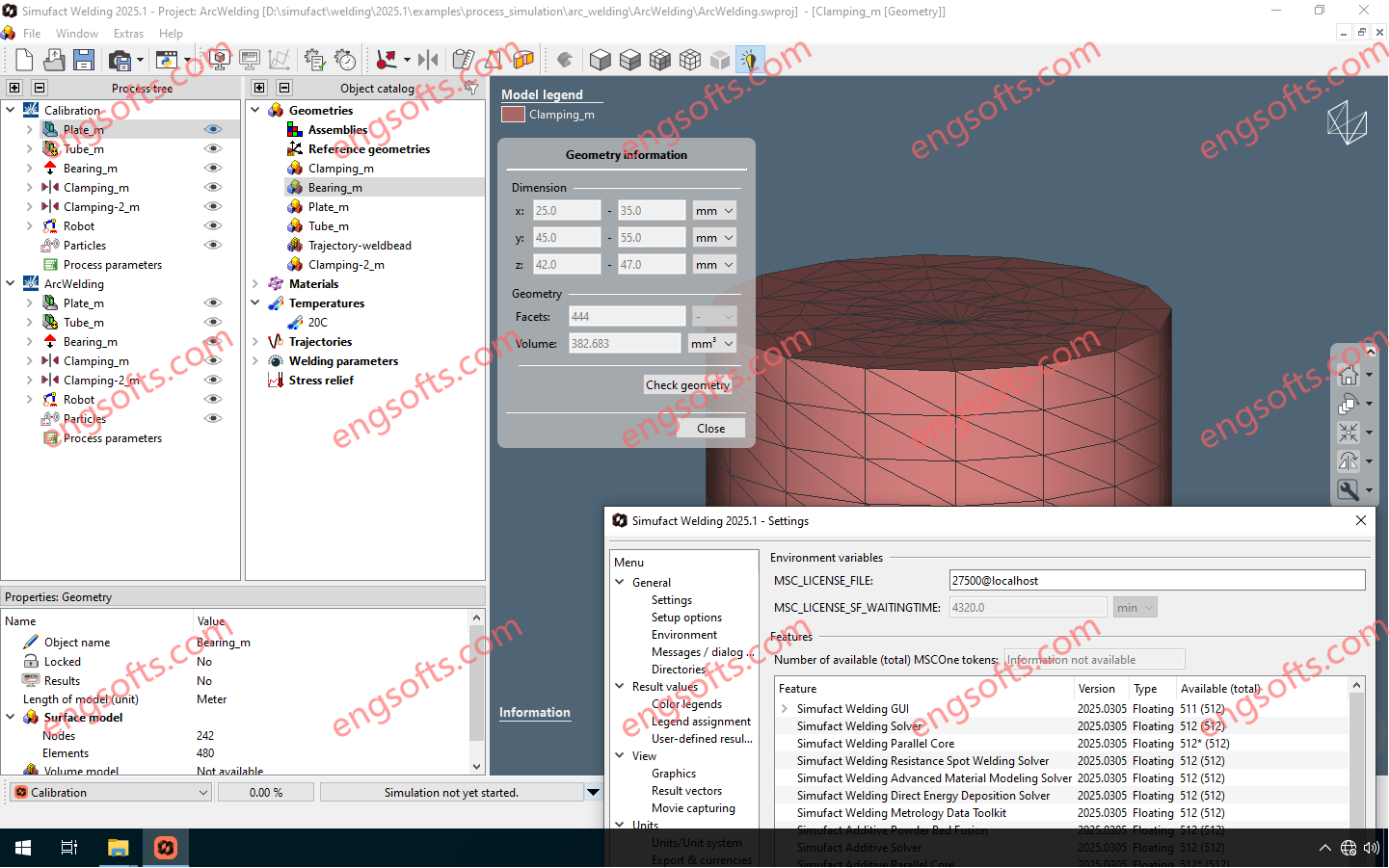

Simufact Welding is designed for modeling and simulation of a wide range of thermal joining processes by means of struct...

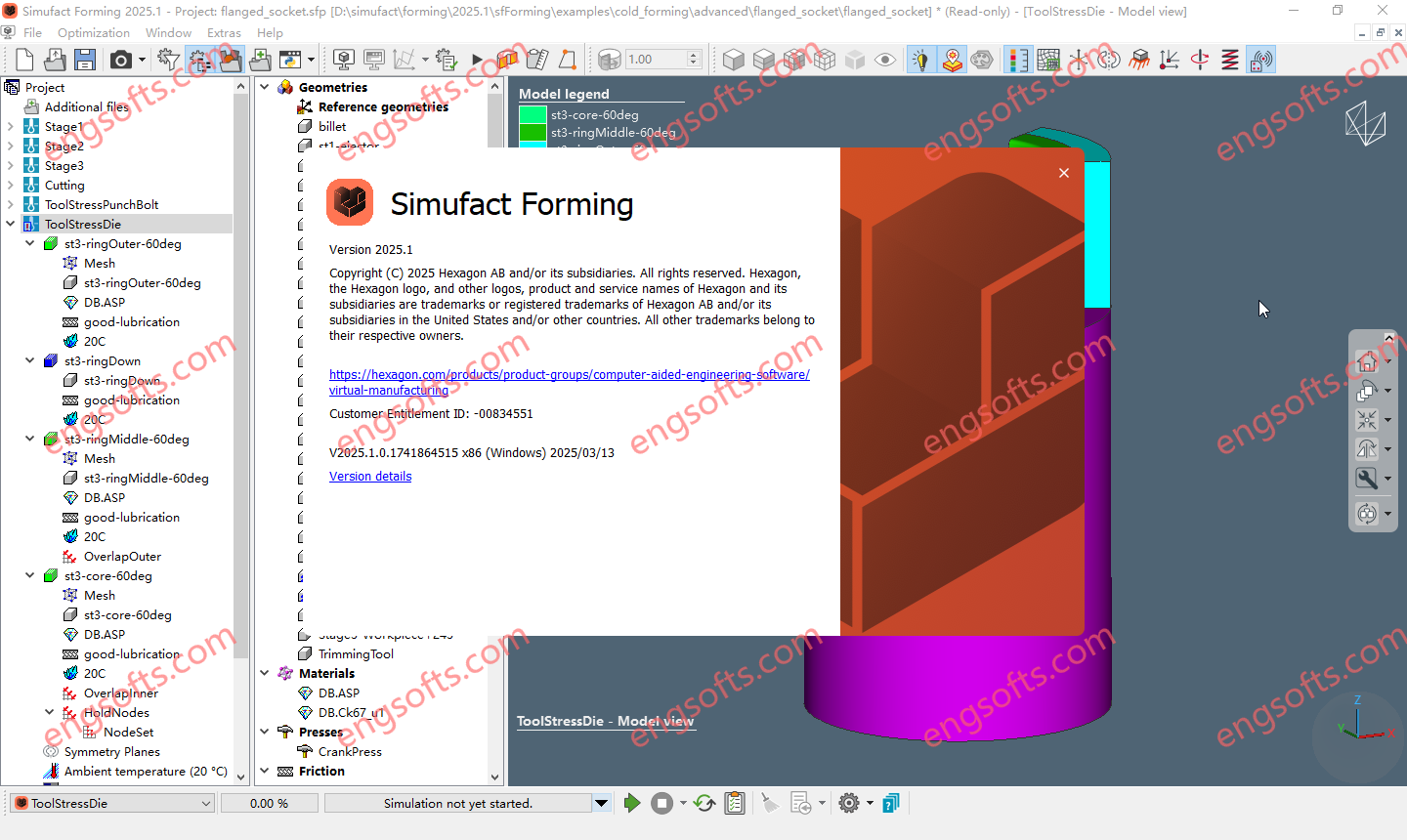

Simufact Forming is a simulation tool for hands-on professionals working with forming technology. Our goal is to focus t...

MSC Nastran 2025.1. This latest version of MSC Nastran brings revolutionary capabilities for topology optimization workf...

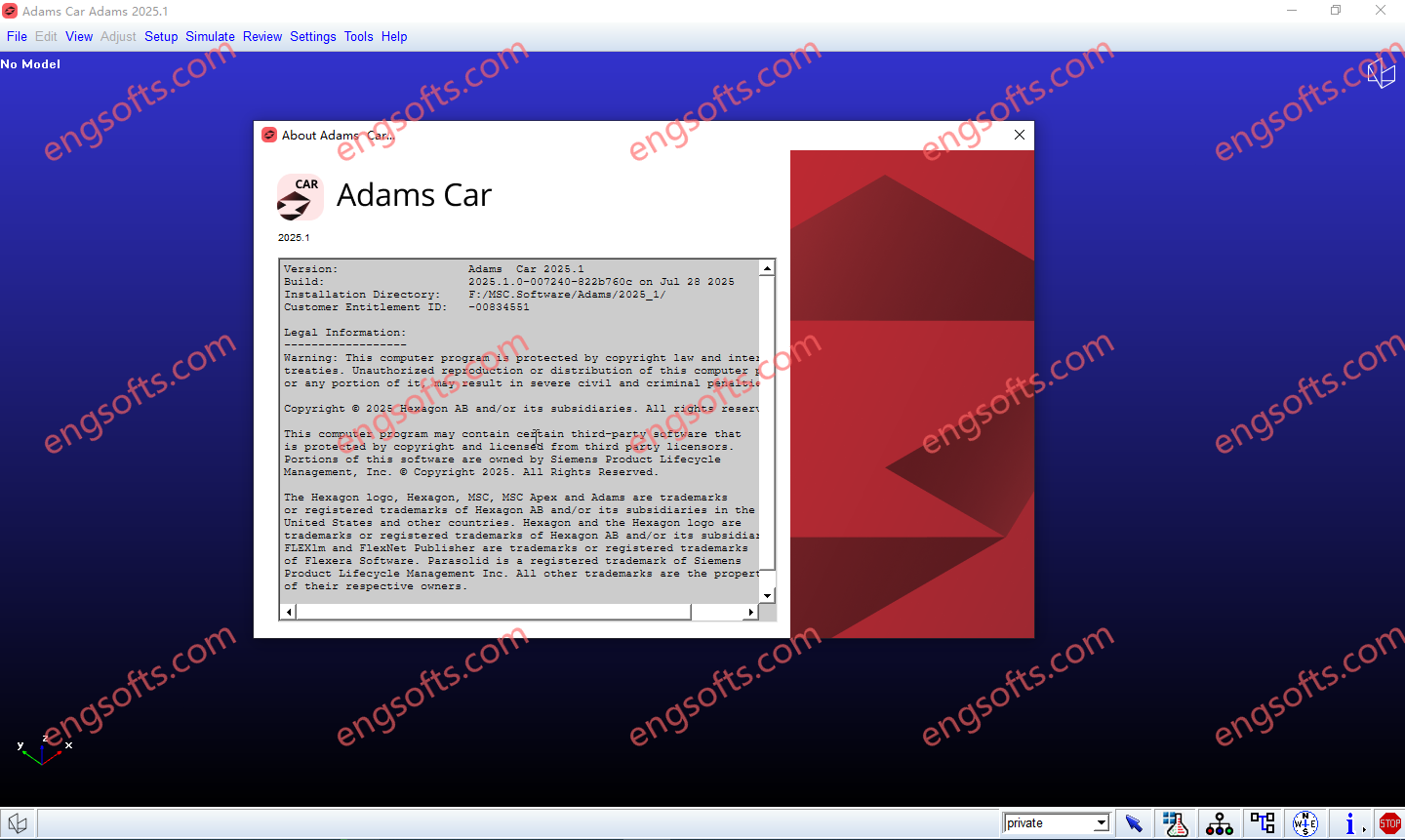

Adams helps engineers to study the dynamics of moving parts, and how loads and forces are distributed throughout mechani...

Simufact Additive is a powerful and scalable software solution for the simulation of metal-based additive manufacturing ...

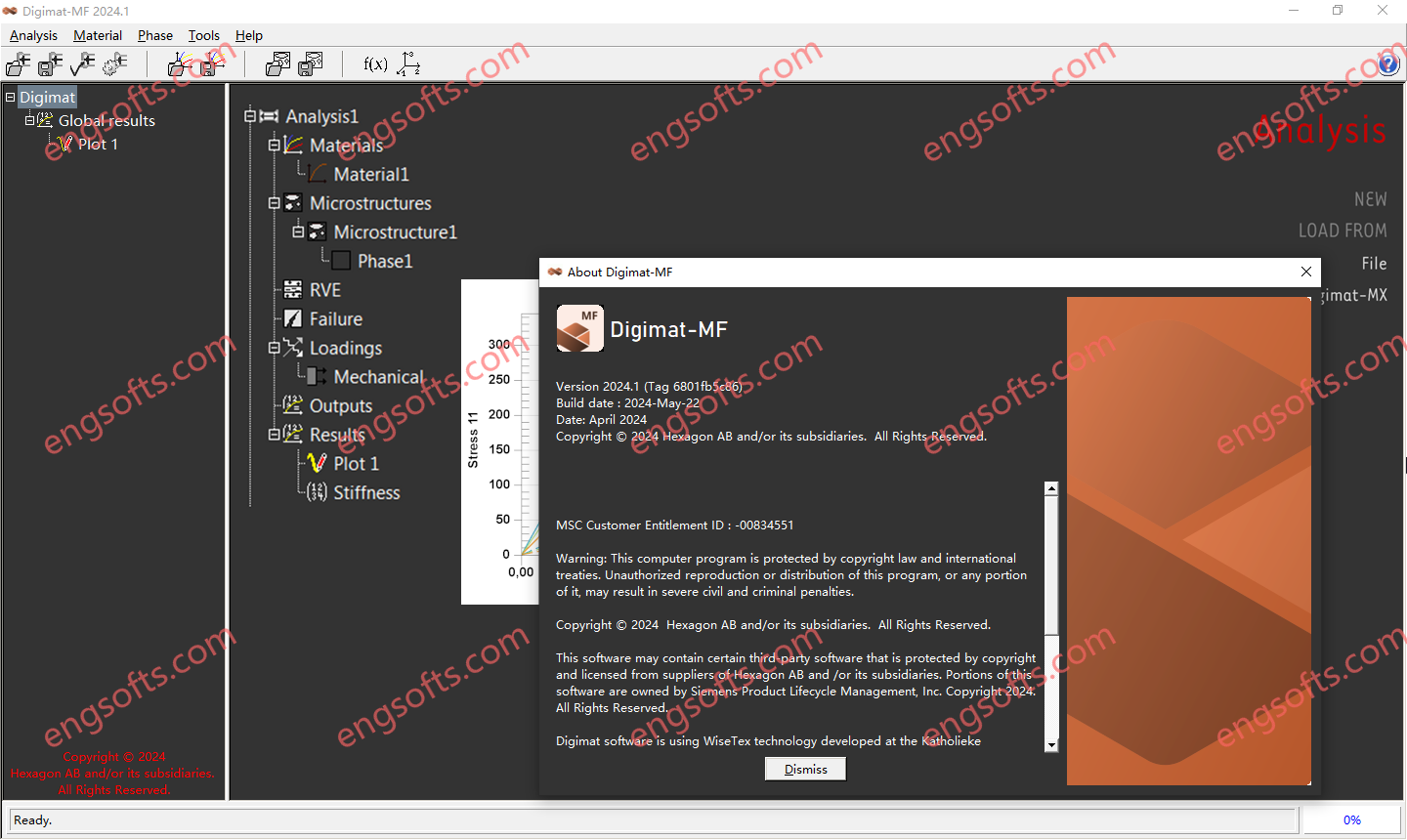

Digimat is the state-of-the-art multiscale material modelling platform focusing on the micromechanical modelling of comp...

AVEVA Process Simulation brings agility to the entire process life cycle—design, simulation, training, and operations. B...