Simufact Forming is a simulation tool for hands-on professionals working with forming technology. Our goal is to focus the software to the practical needs of the users. Our customers confirm the fact that we have achieved a lot in this field.

The operation of simulation software very often requires a lot of expert knowledge to build up and program complex models. This is not the case with Simufact Forming: The user can focus on the engineering-related details of the forming process. He does not have to deal with the physics of the forming process, nor with simulation-specific details. Simufact Forming is application-oriented as well as easy and fast to master.

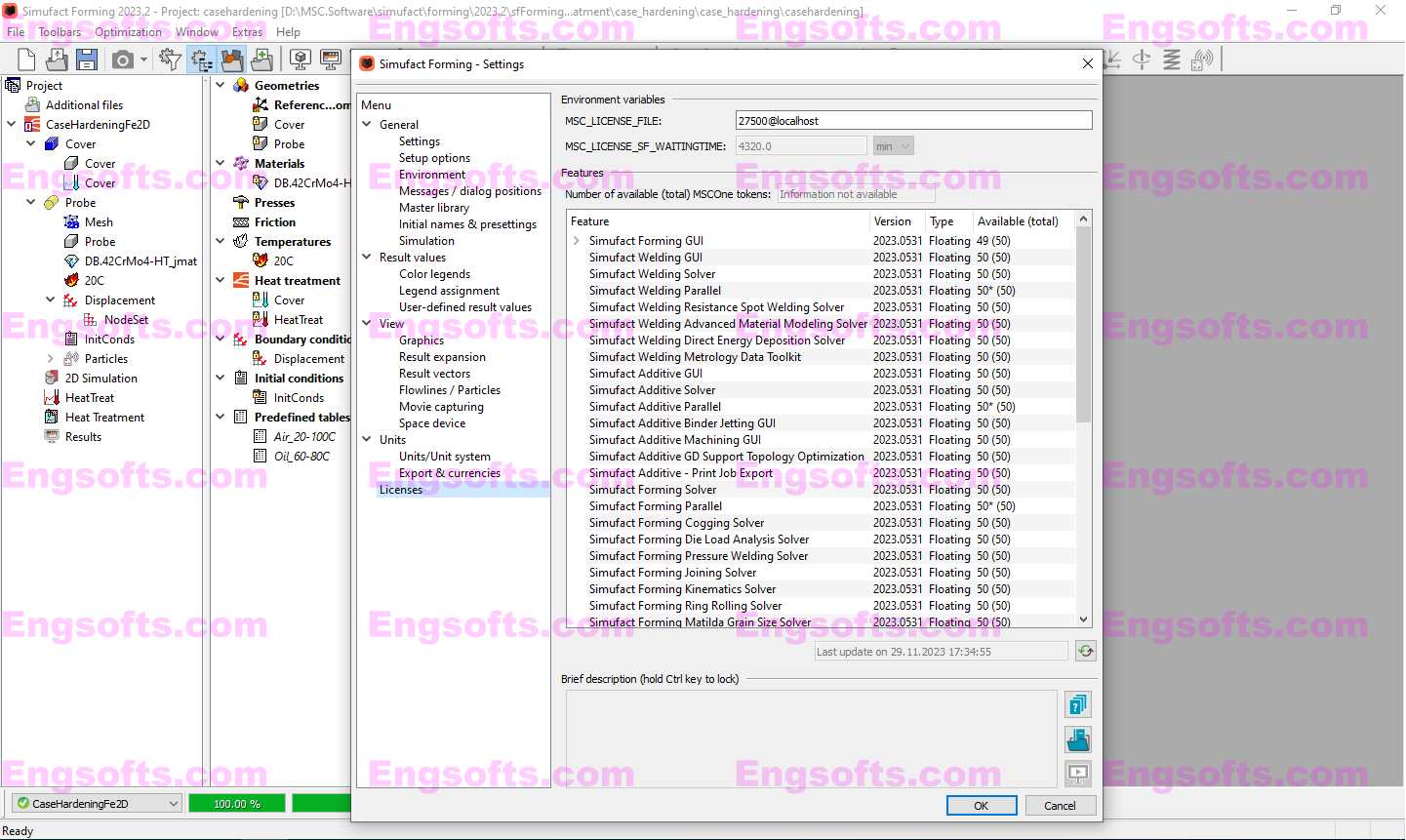

MSC Simulating Forming 2023.2 Tested Picture

Simufact Forming’s standard user interface allows for the software to be easily used and therefore, to become an engineering tool for developers of dies or processes whose daily work is supported and simplified. With a few clicks, all standard-forming processes can be simulated and evaluated.

Simufact Forming stands out due to its easy-to-use design and the fact that it only takes a short time to become familiar with it. The most significant advantages of the hands-on and user-optimized graphical user interface (GUI) are:

- Easy, intuitive Windows style user interface (e.g. drag & drop)

- Very easy and quick to learn

- Forming technology terminology

- Clear structure according to the object area (dies, machines, material etc.), process area (forming operations) and graphic model / results area

- All objects can be provided by databases

- AFS technology (application function sets) simplifies use

- Template technology supports the user during the simulation set-up and conducts process-specific expert adjustments in the background. The user can fully focus on the process to be simulated. Numerical expert knowledge is unnecessary

- Context-based help system for all user inputs with links to further information and example models

- All simulation results can be displayed and evaluated graphicallyusing plots, animations and diagrams while a simulation is still running

- Pre-processing and post-processing are united in one GUI. This reduces the need for training and simplifies the simulation of multi-stage processes

- Extremely easy to generate model variants.